About us

BG Prodcution Sp. z.o.o. was established in Poland in 2010 initially providing service processing of Atlantic Salmon to Scandinavian market in Fresh form. Close allocation to Western European Markets allows BG Production constant market expansion, development as well as high level of competitiveness. Our aim is to transfer the production of seafood products aimed for the European markets back to the local markets. From Polish processing facility we are taking a first step towards a leaner supply chain. Closer to the raw material of fresh salmon and closer to the customers.

BG Production development history:

2010 - beginning of production activity

2011 - production capacity increase, bringing machinery line to highest standard, international food standards certification

2012 - market expansion, establishment of own smokery, installment of additional cod processing line

2013 - building own freezing and storage facilities, buying own transport, development of new products - wide range of both cod and salmon products in both fresh and frozen form

2014 - change of company profile from service processing to 100% ready finished goods sales.

Quality & Traceability

Management

Our management teams are experienced in seafood production.

QC management

We employ certified Food technicians and engineers, that are following a continued program for education and learning.

Accreditations

Our policy is to follow and upgrade systems and people continuously. Apart from in house Q.C systems we are accredited with BRC, IFS and Global G.A.P. as well as HACCP food standards on highest degree.

Control

We are currently implementing a “External Inspections Paradigm” where at any stage in the supply chain of raw material, production or finished products, the company Eurofins Global Control Supply Chain can control and report directly and independtantly on any observations. www.eurofins.com

Certification

We have BRC and IFS certification, besides internal Quality and Control systems we comply to HACCP and have FDA approval and Australia approval. We have Global G.A.P and are working on other Organic approval processes.

Download HQ

Download HQ

Fact sheet

Raw material Sourcing.

Our criterias for raw material are dominated by the requirements of our end customers. Therefore we are aiming for areas with slow growing fish which is consistent with firm meat texture and better colour. Our second aim is to have fish fed with maritime feeding systems, based on sustainable sources, that gives the salmon a natural taste and smell. Our third aim is to have fish that is given good conditions and circumstances for animal welfare, this includes feeding, clean cages and density of max 15 kg fish per m3. Fourth aim is to have the salmon produced into finished products within a maximum of 72 hours after slaughter.

We work steady with several selected farmers in Northern Norway, who are able to meet our requirements.

In production we employ around 230 staff, producing about 10,000 MT of rawmaterial per year.

Our markets are retail and foodservice companies in Australia, France, UK, Germany, Denmark, Sweden, USA and Japan.

Product development

We have a close dialog with our customers on new products that might be interesting for their particular needs. We are continuously scanning the markets for new packaging solutions, new and more sustainable ways of farming our raw material.

We are working closely together with market leaders in the toppings and flavoring industry to develop new flavors or cut to products that can benefit the customers in the market place.

Atlantic salmon

Atlantic salmon from Norway is our raw material base.

Salmo salar has been living in the wild for centuries. Since early 1980’ies it has been the main farmed species, farmed in Norway, Scotland, Ireland and the Faroe Islands.

We work long term with our farming partners, securing us a high quality fish that is fed using sustainable feeding systems and cared about in a way that gives a ethically responsible farmed “Happy Fish”.

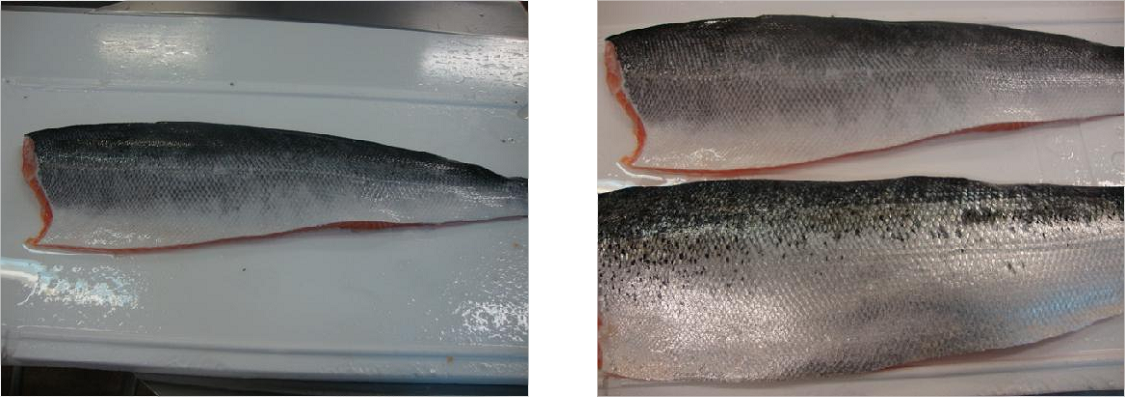

Atlantic salmon fillets

We produce fillets fresh or frozen.

We can pack in any size grade.

We can also pack as vacuum packed with individual weight label.

Our logistical department manages door to door deliveries by land, sea and air.

Atlantic salmon portions

Portons is our main production and we are specialists in producing exactly your specification.

Portons skin/on and skinless.

Size range from 50 to 250 gram - IWP or IQF.

Packed for Retail or Food service

Atlantic salmon special cut

The best part of the salmon, we produce back or belly loin. Can be either defatted or deep skinned in fixed or random weight.

We also offer loins produced after strict sashimi grade specifications.

Steaks in various shapes. Due to our advanced production technology we can offer boneless steaks as an alternative to traditional cross cut steaks.

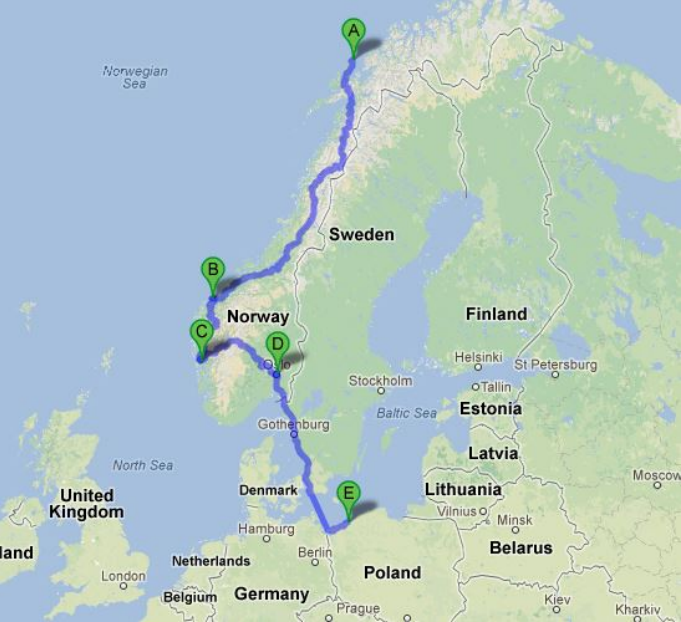

Raw material route

Most of our whitefish raw material comes from partners in Northern Norway. From Andenes North of the Polar circle we have the dayboats landing, only hours old, cod and haddock. Within hours after landing the fish is graded and packed. The freshness is Superb.

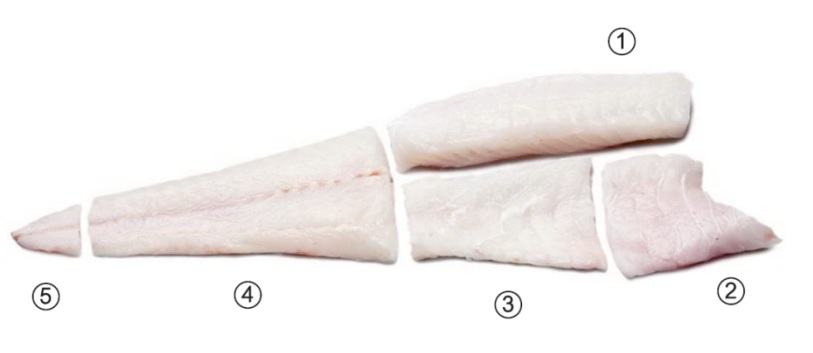

Atlantic White fish products

We produce fillets fresh or frozen. We can pack in any size grade. We can also pack as vacuum packed. Our logistical department manages door to door deliveries by land, sea and air.

Loins: 1/200g, 2/400g, 4/800g, 800g+

Fillets: Skin/on, pbi, skinless, boneless

Tails- & center cut: As per requirement.

ATLANTIC SALMON

SMOKED AND GRAVED

Smoked & Graved salmon available in retail and foodservice packing.

Atlantic salmon

specialty products

In our effort to utilize as much as possible of the rawmaterial, we have developed a range of products, based on mince, ex. pre-fried breaded & bacered burgers. High quality salmon tatar in various shapes and forms. Cubes of salmon for topping in salads and pizza’s.

Production fact sheet

3,500 m2 of production area

Cold storage capacity for 6000 pallets.

Plate freezers & freezer tunnels.

Metal detectors, Graders, Baader filleting, Norfo pinbone removing, Marel portion cutting.

Multivac vacuumpacking machines.

Process lines for fresh and frozen portions and fillets.

Value-added line for Marinated and Smoked salmon.

Own freezing equipment and transport

E-trim – American deep skin

Skin Off

Brown fat = max ca. 2,5cm

E-trim – Euro deep skin

Skin Off

Brown fat = max ca. 3cm

E-trim – Semi deep Skin

Skin Off

Brown fat = max ca. 6cm

E-trim – Normal Skin

Skin Off

Brown fat = whole filet

D-trim plus (D-trim +)

Backfin off

Belly off

Pinbone out

Bellyfat off

Back trimmed

Belly membrane trimmed

Torpedo cut belly

D-trim (D-trim)

Backfin off

Belly off

Pinbone out

Bellyfat off

Back trimmed

Belly membrane trimmed

D-trim minus (D-trim -)

Backfin off

Belly off

Pinbone out

Bellyfat off

Belly membrane trimmed

C-trim plus (C-trim +)

Backfin off

Belly off

Pinbone out

Bellyfat off

Back trimmed

C-trim

Backfin off

Belly off

Pinbone out

Bellyfat off

C-trim minus (C-trim –)

Backfin off

Belly off

Pinbone out

Descaled

Fillets descaled | Top fillet is descaled |

| Buttom fillet is with scale |